Can You Stain A Cutting Board?

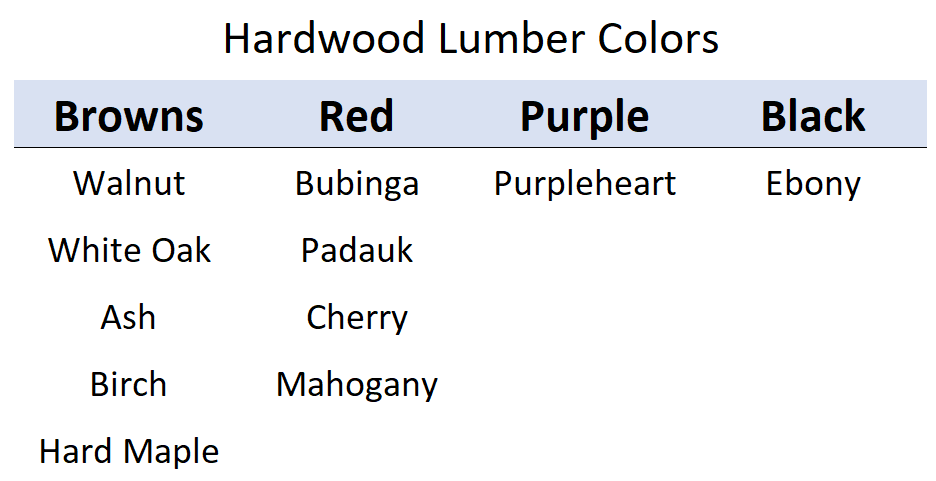

You should not stain a cutting board, instead you can use oils to bring out the natural color of various hardwood lumber species. Wood stains contain toxic dyes and pigments that would contaminate the food when used as a cutting board. If you plan to build a cutting board you can add color by using exotic species of hardwood lumber and applying food safe natural oils. Hardwood lumber species vary from shades of brown to black, vibrant reds, and even bright purple.

Best Wood For A Colorful Cutting Board

You can easily add color to your cutting boards by using various species of hardwood lumber, with the main species being Walnut, Hard Maple, Cherry, Purple Heart, Padauk, Ash, and Birch. Typically woodworkers use multiple types to give a unique look to their cutting boards sometimes even with a pattern. I personally have used Hard Maple which is a very light brown and Walnut a dark brown to create a chevron design with contrasting colors. When I applied the cutting board oil the walnut and hard maple really popped and make the cutting board look amazing. Some species like Purpleheart, Padauk and Ebony can provide extremely vibrant colors naturally. You can find these exotic species of hardwood at your local Woodcraft or hardwood dealer. Some stores will even offer cutting board kits that have an assortment of species precut that only require gluing, sanding and an edge profile if you prefer.

Best oils to maintain the color of your cutting board.

Sometimes simple is better and in this case the best oil for your cutting board is mineral oil. Specifically food grade mineral oil that has met the FDA requirements. Simple mineral oil will allow the natural color of the wood to pop as well as protect against bacteria. Cutting boards will require multiple coats of mineral oil for the initial application until the board no longer absorbs the oil. Also, cutting boards require ongoing maintenance applications of mineral oil to keep the board protected. I personally use the Howard Cutting Board Oil and Butcher Block Conditioner for my cutting boards as well as our butcher block kitchen island. The key I have found is if you see a change in color or slight fading you need to apply another coat of mineral oil.

What glue should you use?

The best wood glue for cutting boards is Titebond III Ultimate Wood Glue and is the most widely used glue by woodworkers. Titebond III is FDA approved for indirect food contact, waterproof, and is non-toxic. When polling woodworkers specializing in cutting boards, they chose Titebond III 96% of the time. Titebond III is chosen by woodworkers for cutting boards for many reasons. The main reasons are that it has been proven to be waterproof as well as FDA approved for indirect food contact.

Face, Edge or End Grain on a Cutting Board?

The best wood grain for your cutting board is end grain, followed by edge grain and lastly face grain. There is no right or wrong way for which grain should be the cutting surface but the longevity of the cutting board will depend on which you choose. End grain cutting boards provide the best cutting surface for longevity but require the most work. Edge grain is also a good option and will allow you to make a thicker board which can be sanded and refinished. Face grain cutting boards are the easiest to build but will show the most wear and tear in a short amount of time. I personally chose to build an end grain cutting board that is 1.5” thick and it has held up great.

See How I Made This Cutting Board!

This was my first cutting board with an optical illusion using walnut & maple edge grain to make a chevron pattern.

Related Articles

If you have any questions, comment below.

Let’s talk about it!